In modern fuel cells and electrolyzers, titanium bipolar plates serve as current collectors, and structural bodies. They need excellent corrosion resistance, high conductivity and optimally designed fluid conduits. Manufacturing requires micro-tolerances and maintaining thin-section integrity.

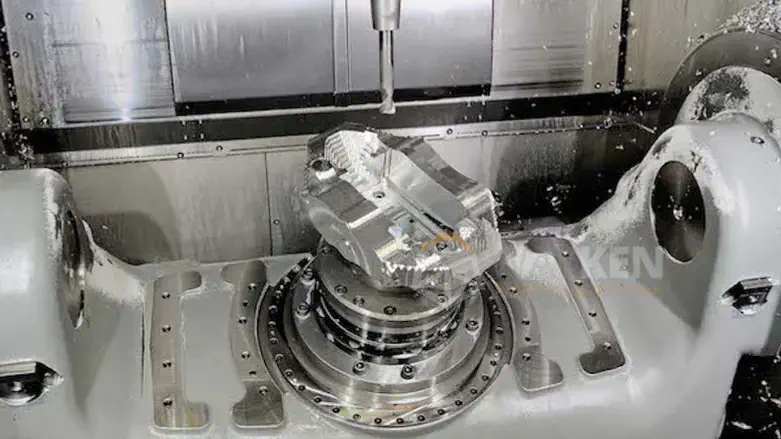

Modern CNC milling services fulfill these requirements through multi-axis machining, adaptive controls and die specific tools. The low thermal conductivity of titanium, its high strength properties, and work-hardening ability makes it difficult to mill and so special machining techniques should be employed. Bipolar plates can be exactly engineered within a CNC metal fabrication system to add performance and efficiency.

Before taking the look at the superior machining solutions that convey these designs into existence, it is necessary to understand the advantages titanium offers as a material.

Titanium as a Strategic Material for Bipolar Plates

Titanium is among the most corrosion-resistant metal especially in acidic and alkaline solution environments, making it an ideal candidate in electrochemical applications. Its high strength to weight ratio compares with many other engineering metals to assure of rigidity in the structure and hence elimination of excess mass to stacks of fuel cells.

But bipolar plate machining of titanium itself does not offer easy tasks. It has rather low thermal conductivity that generates localized heat spikes, which leads to quick wear of the tool and may cause the damage of surfaces.

Moreover, since many thin plate sections are of a size that can be less than 1 mm, distortion can be a big problem during the machining process unless the sections are suitably supported.

In this case, CNC milling services are decisive. They control heat using special cutting geometry, high-pressure coolant delivery, and low radial engagement techniques, and are able to maintain dimensional stability. This strategy in CNC metal manufacturing gives clear cuts on channels, the finish of the surface is within the conductive level, and the structural integrity of the plate is preserved over the lengthy period of operation.

Material properties directly influence the choice of milling method, especially for the increasingly complex channel geometries in modern bipolar plates.

Multi-Axis Milling for Complex Channel Geometries

A titanium bipolar plate is highly efficient on the accuracy of flow channels. Such channels control distribution of reacting gases, off gassing of by-products and have direct impact on fuel cell performance. The profiles of the channels are being made more intricate and integrating micro-features, varying depths, and curvilinear profiles to maximize the dynamics of fluids.

Such work is well suited to five-axis milling platforms. The two can cause the tool to strike the surface at various directions, thus permit efficient machining of complex shapes without having to re-locate the workpiece. Toolpath optimization is of importance in cnc milling services. High speed trochoidal milling is one such strategy, which lowers tool load and also keeps a constant engagement profile so that it does not chatter and over-extends tool life.

Toolpath smoothing and adaptive feed control are also important in CNC metal machining, to reach the necessary ±5μm tolerances. The outcome is the uniform depth of channels coupled with clean edges together with minimum burrs formed, which enhance electrical contact and efficiency in fluid flow. To scale these capabilities, manufacturers increasingly employ digital twin and process simulation tools before production begins.

Digital Twin and Process Simulation Integration

In precision machining of titanium, digital twin technology is starting to become a necessity. Through a virtual representation of the process, engineers can forecast heat and wear of a tool, as well as vibration before the first cut takes place. In the case of CNC milling services, this allows toolpaths, speeds and coolant flow to be pre-adjusted to reduce trial-and-error, scrap and allows bipolar plates made of material needing to meet the same specifications to be made repeatably.

These simulations coupled with IoT-connected sensors in a CNC metal setting provide live data back to the twin. Real-time adjustments to parameters are made to oppose thermal expansion, the varying load on the spindle, or the varying quality of material. It is closed-loop control, where the uptime is maximized, and precision is maximized. Once machining meets its exact specifications, comprehensive verification ensures that every plate conforms to strict dimensional and surface criteria.

Quality Assurance and Post-Machining Treatments

Accuracy in the manufacturing is just one half of it, validation is equally important. Optical metrology, surface roughness, CMM-based dimensional measurement are performed on advanced bipolar plates. During CNC milling services, deviations are detected using in-process inspection systems as one does not have to remove the work piece, leading to handling reduction and a lack of marking the surface during titanium processing.

On CNC metal bipolar plates, additional machining such as chemical polishing and passivation is used to eliminate burrs, smooth micro-asperities and repair the protective oxide layer to provide ultimate corrosion protection. These finishes spin down electrical resistance and increase stack efficiency in high output fuel cells. The mechanical and electrochemical performance are guaranteed by combining high-accuracy machining and special treatments.

The manufacturers are in a position to turn their attention to the scaling of next-generation fuel cell system production with quality and finishing processes in operation.

Scaling Production for Next-Gen Fuel Cell Systems

Driven by the growth of fuel cell applications in everything to vehicles to grid-scale storage, scalable, cost-effective titanium bipolar plate manufacturing is gaining momentum. Conventional systems cannot reach high throughput without sacrificing precision at the micron level. This is defeated by modern CNC milling services use automation, robot gripping and high-capacity tool changers to maintain speed and not to sacrifice quality. On-demand machine monitoring monitors spindle health, tool life, and coolant so as to eliminate downtime.

Modular fixturing occurs in CNC metal fabrication and allows several plates on setup which maximizes the use of the spindle. Just-in-time supply and predictive maintenance maintain the flow of production and make it efficient.

Such technology developments are providing the potential of large-scale mass production of high-quality plates, which gets the cleaner and more efficient energy systems, directly. Machining innovations such as these are critical enablers of the emerging hydrogen economy.

Conclusion

Advanced titanium bipolar plates are based around CNC milling, which offers smart process control combined with precision engineering. Manufacturers produce complicated geometries with minute tolerances and exceptional surface integrity of fuel cells via CNC milling services. Production is being accelerated, becoming more dependable, and economically feasible due to the advancement in CNC metal machining such as digital twins and automation.